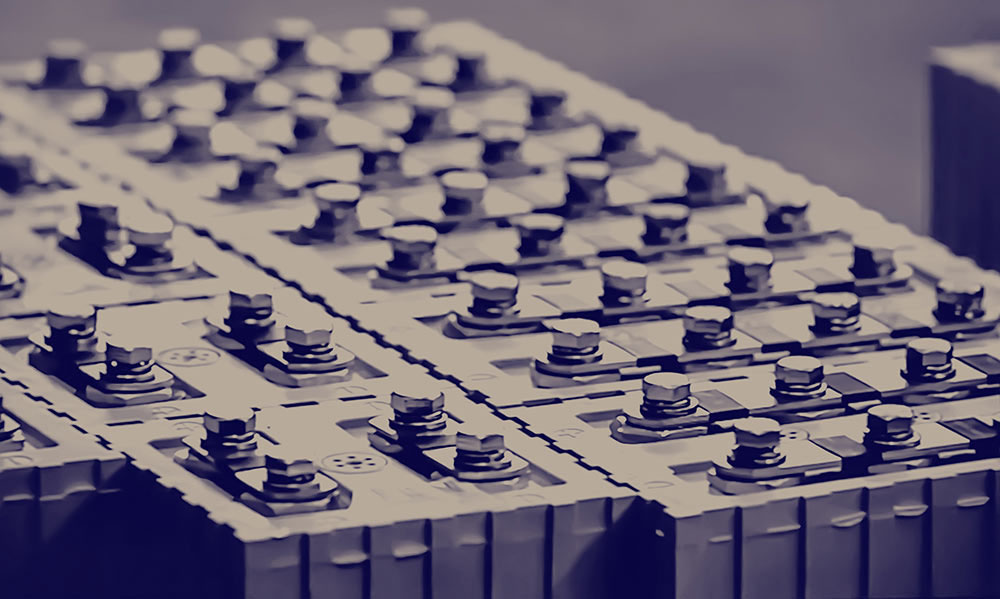

Car manufacturers – and governments too – have set their sights on 2035 and the end of fossil fuel mobility, thus emphasising the swap for better battery life cycle management. Electric vehicle (EV) manufacturers have likewise acknowledged the need to map (not scrap) lithium-ion batteries, so they can be reused for energy storage or recycled for metals recovery. The same applies to the lithium-ion batteries that power portable electronics such as smartphones. However, there are still many challenges to overcome.

Both industries face a challenge to evolve from a take-make-dispose system to a circular economy. However, in the face of climate change and rising consumer expectations around sustainable resource management, the pressure is growing to show meaningful change. Could blockchain battery recycling help move these industries past the tipping point for rapid change?

The battery revolution has its detractors, but when you look at the figures, the case for transformation becomes clear. By 2030, it is estimated there will be over 18 million electric vehicles on the road. Battery technology could enable the transport and power sectors to reduce emissions by 30% by 2030, on track to meet the 2°C goal of the Paris Agreement. According to the World Economic Forum, this battery revolution could also create 10 million jobs, add $150 billion to the global economy and provide electricity to 600 million people for the first time.

When batteries are sourced, manufactured and recycled responsibly, they will fuel sustainable development. Everledger helps clients and partners to achieve traceability and maximize the life cycle value of products such as portable electronics and EV batteries. Our provenance-tracking solution drives transparency along clients’ supply chains of critical metals and minerals, combining blockchain technology with AI, IoT and nanotechnology to enable traceability in a secure, unalterable and private platform.

As government regulation and consumer demand become ever stricter, our blockchain solution facilitates traceability, enabling easier compliance. We are ISO27001-certified, evidencing the highest level of trust on information security and data protection.

In the same way that rising public awareness around ‘blood’ or conflict diamonds has resulted in improved mining practices, the same can be achieved for ‘conflict minerals’, where unverified extraction of critical minerals benefits armed groups. The world has woken up to the need for a circular economy. Incentive mechanisms and methods are now needed to further raise awareness and build momentum for change.

Since 2017, Everledger has committed to supporting the Global Battery Alliance, with a view to raising ever more awareness around the challenges and opportunities of a sustainable battery value chain.

Last year, we were awarded Phase 1 funding by the United States Department of Energy for two pilot programs to trace the life cycle of lithium-ion batteries using blockchain and Internet of Things (IoT) technologies.

The first battery recycling project is a collaboration with Ford Motor Company, connecting stakeholders in its electric vehicle battery life cycle to ensure optimal management and responsible recovery at end-of-life. The second pilot focuses on a platform to inform and reward consumers for recycling portable lithium-ion batteries and the products they power.

These two pilot programmes will work toward sustainable objectives, by ensuring EV and portable electronics batteries can be tracked for efficient life cycle management. Both will utilize the latest identification, data capture and blockchain technologies to give batteries a bespoke digital identity (or ‘battery passport’). Through intelligent labelling solutions, physical objects will be seamlessly connected with the Everledger blockchain platform, enabling higher security, record immutability and privacy. Stakeholders can gain full visibility over a battery’s location, condition, health score, and which metals could be recycled for use in new batteries.

In New Zealand, Everledger is an advisor to the New Zealand Battery Industry Group (B.I.G.) regarding traceability and supply chain transparency for lithium-ion batteries. We’ve been working with B.I.G. to develop a circular product stewardship scheme for EV batteries, enabling the ability for them to be repurposed for energy storage. EV batteries may have around 70% to 80% of their capacity remaining when they reach the end of their useful life in a vehicle at about 10 years and can be repurposed for energy storage, extending life for another 10-15 years.

The battery value chain provides a fascinating test case for the supportive environment needed in a circular economy. Rapidly falling technology costs are creating major opportunities to reduce waste. For example, blockchain and IoT can keep track of valuable products and materials much more cheaply than in the past, radically increasing opportunities to recover them.

We’re moving towards a world where all materials will be traced from the moment they are extracted, through to first use, re-manufacture and eventual deconstruction and re-use. In the future, much of natural mining can be replaced by urban mining, where societies extract resources from previously manufactured products, such as the components inside an old mobile phone.

The proliferation of the circular economy will rely on governments taking a prominent role – and being invited to collaborate by the private sector – rather than waiting for development to run its course. They can strongly influence industries through urban planning, infrastructure investment and mobility systems to integrate new technologies effectively and avoid the risk of massive structural waste.

City authorities must also recognize the threat of ‘rebound effects’ from the circular economy. Technology drives down prices, which is good news. But as relative prices decrease, consumers tend to use more individualized transport. In other words, the less the stuff costs, the more we want to use and waste. Policymakers can act to avoid the potential 20% rebound caused by increased prosperity. They can introduce waste regulations that stop treating waste as an environmental safety hazard, but rather as a source of valuable materials and products.

Adaptation is not only the right thing to do, but it is also the smart thing to do as it generates economic, social and environmental benefits. With every new initiative focused on the responsible recycling and re-use of natural resources, we stride closer to achieving a more thorough and permeating circular economy.